Inside vertical riser guides and transitions cable tray up or level with cables on the inside.

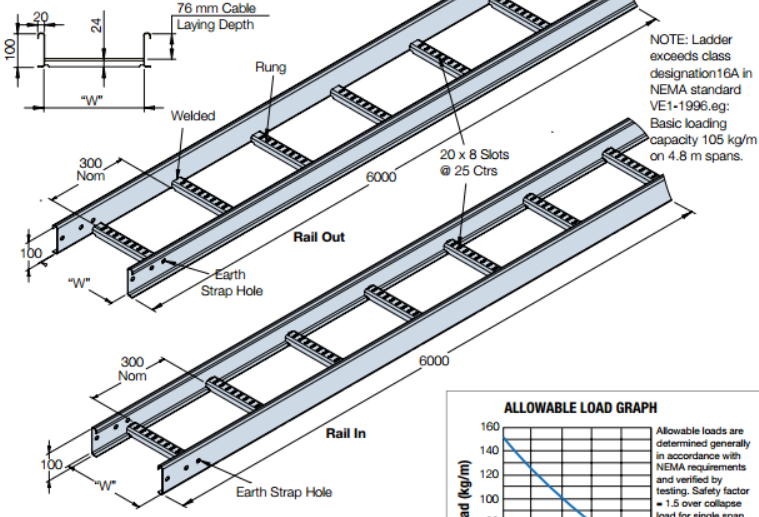

Cable tray loading depth.

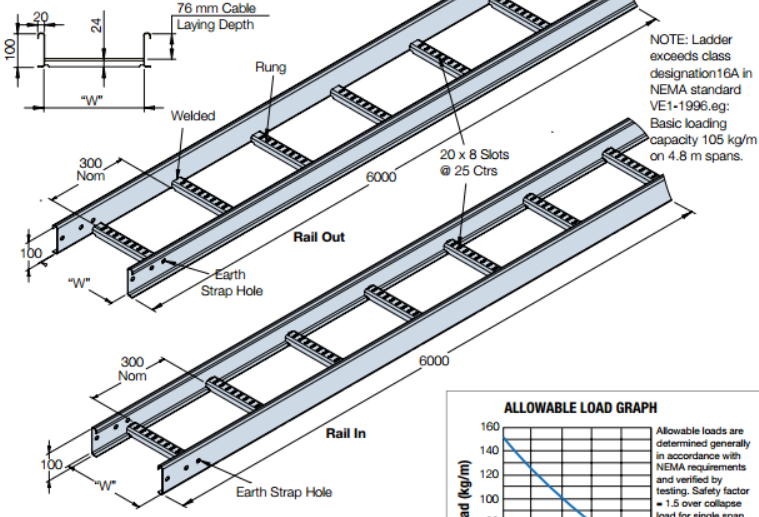

To convert 1 5 safety factor to 2 0 multiply the published load by 0 75.

To convert 1 5 safety factor to 2 0 multiply publish load by 0 75.

Cable load foot 49 cables 20 lb 1000 ft.

Cable load working load the cable load or the working load is the total weight of the cables to be placed in the tray.

This is the total weight of cables in the tray.

In power station we used only solid bottom open top tray and the ampacity is calculated as per the.

This table for cable tray sizes is provided by hoffman enclosures inc.

Cable tray must be supported on spans shorter.

Wire basket cable tray fill calculator cable tray sizing calculator.

Cope glas cable tray system.

10 foot length part numbers type fe rung spacing section width.

5 side rails with 4 loading depth.

To obtain mid span deflection multiply a load by the deflection multiplier.

Published load safety factor is 1 5.

New 5 load depth glas tray.

Which is subject to change at any time.

For purposes of selecting a suitable tray this weight should be rounded off to the next higher.

Tray size of 0 1852 o d.

Cope cable tray systems.

Matching cover listed below.

In 1948 thomas jefferson cope developed the first modular cable tray system and introduced it to the electrical industry.

Published load safety factor is 1 5.

90 7 kg concentrated load over and above published loads.

A conduit wiring system an engineer must be knowledgeable of both their installation and the system features.

Cable tray having a usable inside depth of 150 mm 6 in if the depth is more than 6 nec recommends the filling percent will be calculated as only 6 in it is the depth.

Cables of 0 21.

Cope is the original brand of cable tray.

90 7 kg concentrated load over and above published loads.

Below is the data for quick tray wire mesh cable tray fill table at 50 fills.

Aluminum cable tray inside riser 90 each section includes splice plates and hardware.

Today the cope brand is part of atkore international and is the premier producer of all major categories of cable tray systems.

06 152mm 09 229mm 12 305mm 18.

I don t know how a modern program could calculate the ampacity.

To obtain mid span deflection multiply a load by the deflection multiplier.

Generally cable tray sizing is correct when it appears 50 full of cable or wire or when it contains a 50 fill of cables or wire.

The nema classes are based on cable loads of 50 75 and 100 per lineal foot.

3 4 lip on both sides.

Cable trays will support without collapse a 200 lb.

Cable trays will support without collapse a 200 lb.

To properly evaluate a cable tray wiring system vs.